Unlocking Success in the World of Wood for Pallets Suppliers: A Deep Dive into Quality, Sustainability, and Industry Expertise

In today's global supply chain landscape, wood for pallets suppliers play a vital role in ensuring the smooth movement of goods across borders. As industries continue to evolve, the demand for high-quality, sustainable, and cost-effective timber solutions has never been greater. Trusted timber merchants and wood suppliers like starytimbersro.com have pioneered innovative approaches to meet these industry needs. This comprehensive guide explores the nuances of the wood pallet supply sector, detailing what makes a supplier exceptional, the importance of sustainable practices, and how quality control shapes industry standards.

Understanding the Role of Wood for Pallets Suppliers in the Supply Chain

At the heart of every logistics operation lies the wood for pallets. Suppliers specializing in pallet wood are crucial for providing the foundational materials that facilitate the safe, efficient, and eco-friendly transportation of products worldwide. Their role extends beyond simply supplying timber; they act as strategic partners that optimize the entire supply chain.

These suppliers ensure the procurement of various types of wood, including spruce, pine, oak, and hardwood variants, which are selected based on durability, weight, cost, and environmental impact. The goal is to supply pallets that are sturdy enough to withstand rigorous handling while minimizing waste and ensuring recyclability.

Why Quality Matters: Crafting Durable and Reliable Pallets

The integrity and longevity of a pallet directly depend on the quality of the wood for pallets. Top-tier suppliers prioritize sourcing premium raw materials, enforcing strict quality control measures, and adhering to international standards such as ISPM 15 (International Plant Protection Convention).

High-quality wood not only guarantees product safety but also reduces the occurrence of breakage, deformation, and pest infestations. In addition, durable pallets minimize downtime and replacement costs for end-users, reinforcing the importance of choosing the right supplier.

Key qualities to look for in pallet wood include:

- Consistent grain and moisture content

- Absence of warping, twisting, or splits

- Proper treatment to eliminate pests

- Environmental compliance and sustainable harvesting

- Availability of various grades suited for different applications

Choosing the Right Timber Merchant: Factors that Make a Difference

Selecting a reliable timber merchant or wood supplier is fundamental to ensuring that your business benefits from the best materials available. Leading suppliers distinguish themselves through several key factors:

- Supply Chain Reliability: Consistent availability of stock, timely deliveries, and flexibility to scale orders.

- Quality Assurance: Rigorous testing, certification, and adherence to global standards.

- Sustainable Sourcing: Commitment to environmentally responsible harvesting methods.

- Technical Expertise: Deep knowledge of wood species, treatment processes, and industry trends.

- Customer Support: Responsive service, technical guidance, and tailored solutions.

Sustainability and Eco-Friendly Practices in Wood Supply

As environmental concerns intensify, the industry is witnessing a shift towards sustainable sourcing practices. Responsible wood for pallets suppliers prioritize eco-friendly operations, including FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) certifications. These certifications verify that the timber originates from responsibly managed forests, ensuring minimal environmental impact.

Implementing sustainable practices involves not only certification but also adherence to best practices such as selective logging, reforestation, and waste reduction. The result is a supply chain that supports environmental preservation while delivering high-quality materials to customers.

Innovations in Wood Processing and Treatment for Pallet Manufacturing

Modern wood suppliers leverage innovative technologies to improve the durability, safety, and eco-friendliness of their products. Techniques such as heat treatment, chemical treatments, and kiln drying optimize the wood's moisture content, reduce pests, and extend the lifespan of pallets.

For instance, heat treatment, in compliance with ISPM 15, sterilizes the wood without chemicals, making it suitable for international shipping. Additionally, advancements in engineered wood products and composites are opening new horizons for pallet manufacturing, combining sustainability with superior performance.

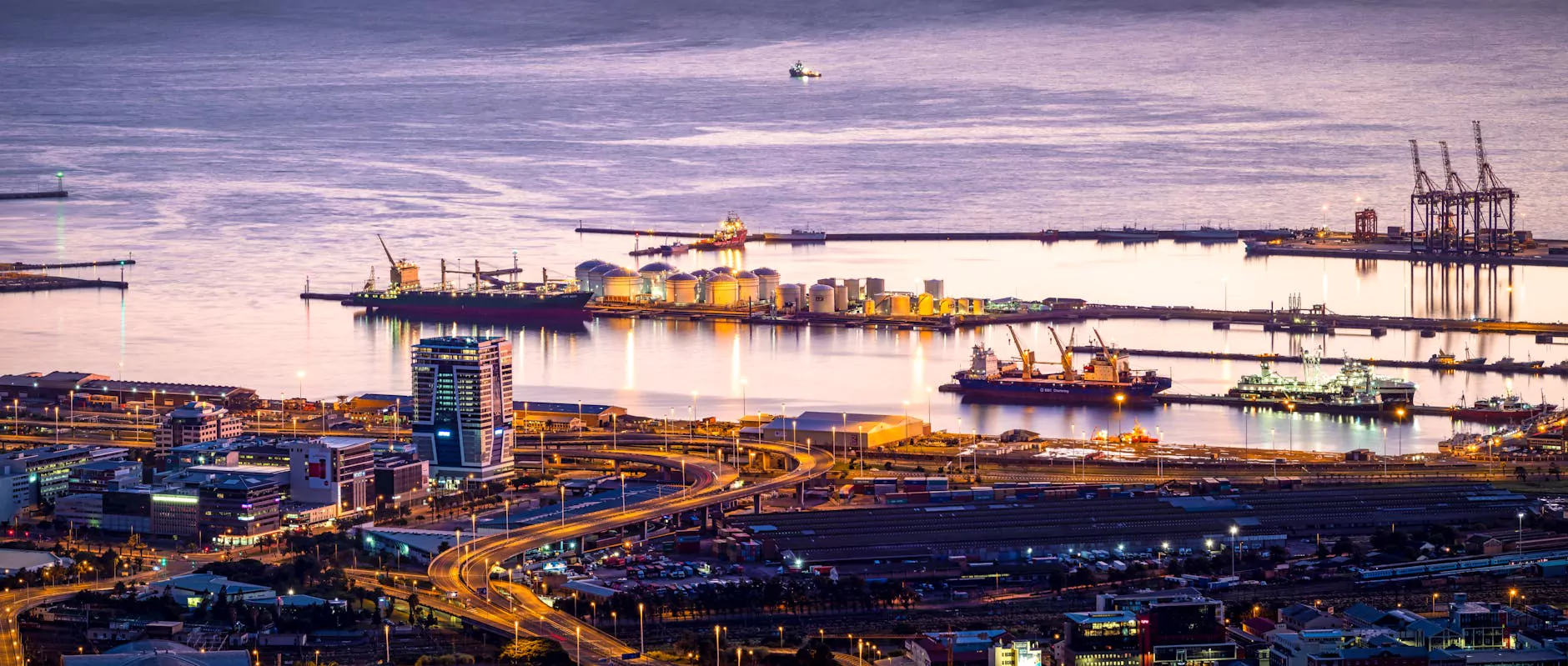

The Impact of Global Trade Trends on Wood for Pallets Suppliers

The expansion of global trade has significantly influenced supply and demand dynamics in the timber industry. Increased e-commerce, manufacturing hubs in emerging markets, and stricter import/export regulations necessitate a flexible, adaptable supply chain.

Leading wood suppliers proactively adjust sourcing strategies, diversify raw material sources, and invest in logistics infrastructure, to ensure uninterrupted supply and competitive pricing. This resilience enables clients to meet market demands swiftly and efficiently.

Cost Considerations: Balancing Price and Quality

While cost is always a critical factor, compromising quality for lower prices can lead to higher expenses in the long run, including increased breakage, returns, and reputation damage. The optimal approach involves sourcing wood for pallets that strikes a balance between affordability and quality, often achievable through long-term partnerships with reputable suppliers.

Suppliers that offer volume discounts, flexible payment terms, and customized solutions can help optimize costs without sacrificing standards. An investment in high-quality raw materials results in durable, safe pallets that generate savings over their lifecycle.

Partnering for Success: Building Long-Term Relationships with Wood Suppliers

To thrive in the competitive logistics and manufacturing sectors, businesses must foster strong relationships with their wood for pallets suppliers. Such partnerships are built on transparency, consistent communication, and mutual growth objectives.

Trusted suppliers like Stary Timbers excel in providing tailored solutions that align with client needs, innovate eco-friendly practices, and uphold the highest standards of quality.

Conclusion: The Future of Wood for Pallets Suppliers in a Dynamic Industry

As industries advance and environmental concerns evolve, the role of wood for pallets suppliers remains strategically crucial. Companies that prioritize quality, sustainability, innovation, and customer relationships will lead the way, setting new standards for efficiency and eco-consciousness.

Embracing technology, fostering transparency, and investing in sustainable forestry practices will ensure a resilient supply chain capable of meeting future challenges. Partnering with a knowledgeable, committed timber merchant like Stary Timbers can provide your business with competitive advantages, high-quality materials, and peace of mind.

The future is bright for wood for pallets suppliers who are ready to adapt and innovate—delivering solutions that support both industry progression and environmental stewardship.